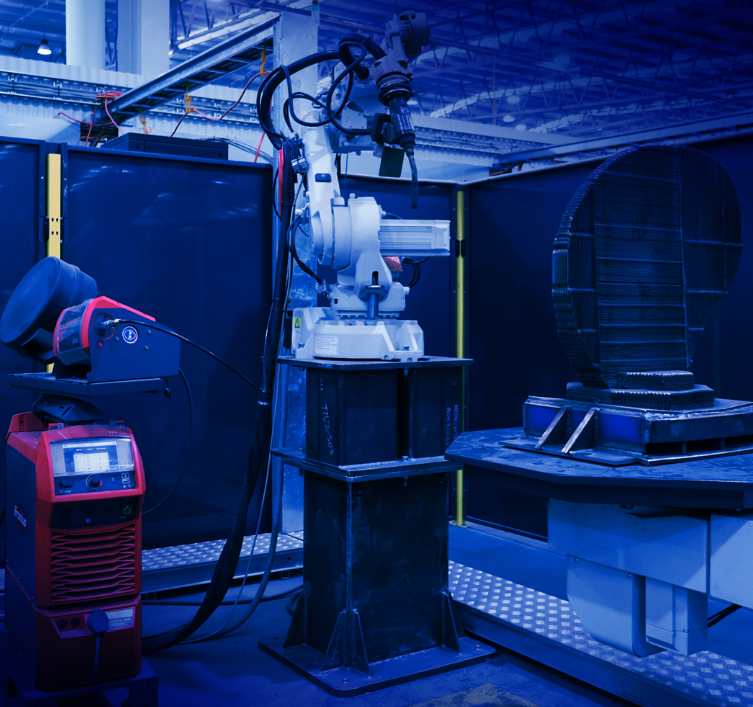

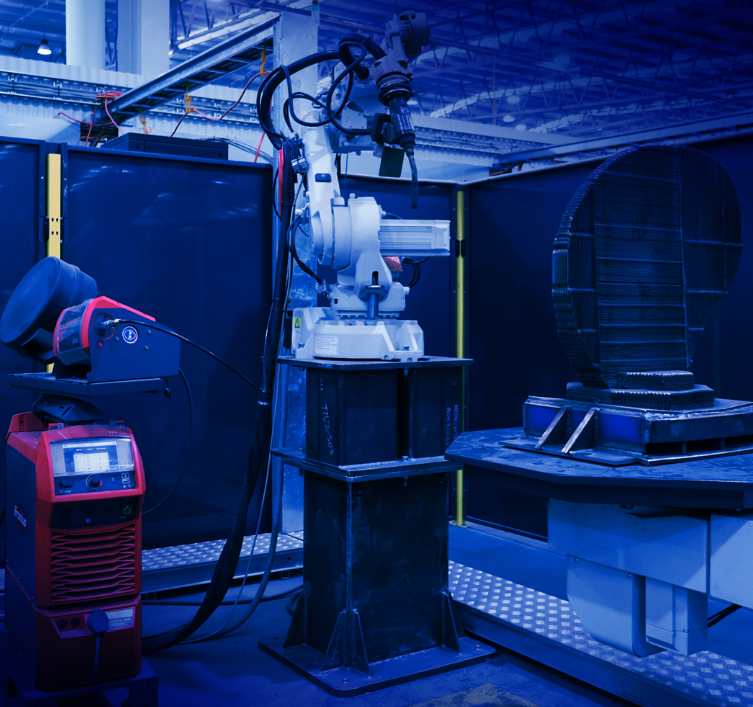

Australian 3D printer producer AML3D has obtained an order for 2 of its ARCEMY Small Version 2600 3D printers from US Navy submarine part provider Laser Welding Options (LWS).

The deal, value AUD$0.70 million (US$0.46 million), will see LWS lease the 3D printers for 12 months, with an choice to buy them outright at any level through the lease time period. A 12-month software program licensing and ongoing technical assist are additionally included.

These two 3D printers will add to the corporate’s present ARCEMY 2600 system, which it acquired in September 2023. Collectively, they are going to assist LWS’s ongoing efforts to speed up the qualification of ARCEMY Nickel Aluminum Bronze (NAB) parts for the US Navy’s Submarine industrial base.

By leasing two further Wire Arc Additive Manufacturing (WAAM) techniques to LSW, AML3D continues to advance its US ‘Scale-Up’ technique. This initiative seeks to handle provide chain challenges throughout the US Division of Protection (DoD), with a concentrate on US Navy submarines. In keeping with AML3D, ‘Scale-Up’ delivered over AUD$12 million from orders in 2023.

AML3D will airfreight the 2 ARCEMY 2600’s from Adelaide, South Australia to LSW’s base in Houston, Texas. The 3D printers are anticipated to be operational inside 8 to 10 weeks.

“This new order for two further ARCEMY techniques helps deepen our relationship with LWS and illustrates how essential our superior manufacturing expertise is to the US Defence sector,” commented AML3D CEO Sean Ebert. “AML3D ARCEMY techniques can produce greater high quality parts, quicker and with much less waste than conventional manufacturing which is driving demand from the US Navy and the broader US Navy submarine industrial base provide chain.”

AML3D continues US Navy ‘Scale Up’ technique

International geopolitical insecurities, environmental challenges, and assaults on worldwide delivery within the Pink Sea have led to the US DoD’s elevated adoption of additive manufacturing expertise. By bolstering its 3D printing capabilities, the US navy hopes to ascertain resilient, aggressive, and sustainable home provide chains of important steel components.

Tapping into this demand, AML3D’s is working to develop into some extent of want, additive manufacturing answer for the US Navy’s Submarine industrial base by means of its ‘Scale Up’ technique. The corporate’s new collaboration with LSW is the newest in a protracted line of offers to extend adoption of its ARCEMY expertise into the broader US Navy provide chain.

Earlier this 12 months, it was introduced {that a} large-scale ARCEMY ‘X-Version 6700’ 3D printer had been commissioned on the US Navy’s Additive Manufacturing Middle of Excellence (AM CoE) in Danville, Virginia. Value AUD$1.1 million, the WAAM system is the corporate’s largest steel 3D printer and was delivered by way of AML3D reseller Phillips Company.

This adopted the information in November 2023 that the corporate had obtained round AUD$5 million value of orders for its ARCEMY expertise from US Protection contractors Cogitic Company and Austal USA.

Value AUD$2.5 million, Cogitic’s deal outlined the supply of steel 3D printed components for US Navy submarines. Austal USA’s AUD$2.2 million noticed an ARCEMY WAAM 3D printer put in at its Virginia-based Superior Manufacturing Centre.

Earlier in 2023, AML3D obtained a USD$0.6 million NAB part order to assist the US Navy’s submarine program. By this deal, the corporate was contracted to supply a 3D printed prototype half weighing round 1 tonne which was to be delivered within the area of 22-24 weeks.

2023 additionally noticed the set up of an ‘X-Version 6700’ 3D printer on the US Division of Vitality’s Oak Ridge Nationwide Laboratory. The 3D printer, value roughly AUD$1.0 million, was acquired to speed up the US Protection industrial base’s superior manufacturing capabilities.

Away from the US DoD, AML3D not too long ago signed an AUD$0.35 million contract with Toolcraft Australia. This deal will see the corporate provide a 6-part nozzle meeting for the Australian Authorities’s Protection Science and Know-how Group (DSTG) challenge. AML3D hopes that the supply of this meeting will spotlight the power of its WAAM 3D printing expertise to supply components in much less time than conventional manufacturing strategies.

After initially delivering a 4-stage nozzle meeting, AML3D added a further two phases of an Aluminium ER5183 nozzle meeting to deliver the overall to 6. Two phases are anticipated to be delivered this monetary 12 months, with the remaining 4 phases anticipated in FY25.

Securing US protection provide chains with 3D printing

The US Navy’s efforts to construct a powerful 3D printing provide chain aren’t restricted to AML3D. It was introduced earlier this 12 months that Bechtel Plant Equipment Inc. (BPMI) had chosen Velo3D’s totally built-in steel 3D printing system to assist the U.S. Naval Nuclear Propulsion Program.

The chosen steel additive manufacturing answer will characteristic Velo3D’s Sapphire XC massive format 3D printer calibrated for chrome steel 415. Supplies firm ATI will function this method at its newly established Florida-based additive manufacturing facility. By integrating Velo3D’s 3D printing expertise, BPMI and ATI hope to scale back lead instances for vital parts required for the Naval Nuclear Propulsion Program.

Moreover, Rocket engine producer Ursa Main not too long ago signed a contract with the US Navy to design, produce and take a look at a 3D printed strong rocket motor (SRM) for the Customary Missile (SM) program. Right here, Ursa Main will leverage its Lynx steel 3D printing system to fabricate the prototype SRMs designed to energy the US Navy’s SM-2, SM-3, and SM-6 missiles. It’s hoped that this deal will meet demand for the manufacturing of key missile parts on US soil.

Wish to assist choose the winners of the 2024 3D Printing Trade Awards? Be part of the Knowledgeable Committee at this time.

What does the way forward for 3D printing maintain?

What near-term 3D printing traits have been highlighted by trade consultants?

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information.

It’s also possible to observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits an ARCEMY Small Version 2600 3D printer. Photograph by way of AML3D.