Netherlands-based impartial 3D printing resin producer Liqcreate has unveiled its newest resin, Liqcreate Inflexible Professional. The brand new materials targets particular use instances the place options had been beforehand sparse.

Liqcreate Inflexible Professional is a black photopolymer resin purpose-made for engineering purposes. This resin is formulated to supply chemical resistance, high-temperature tolerance, and important energy and rigidity. These traits make Liqcreate Inflexible Professional a flexible materials appropriate to be used in numerous industries, reminiscent of engineering, automotive, electronics, and oil & fuel.

A chemical-resistant and heat-defiant resin for versatile purposes

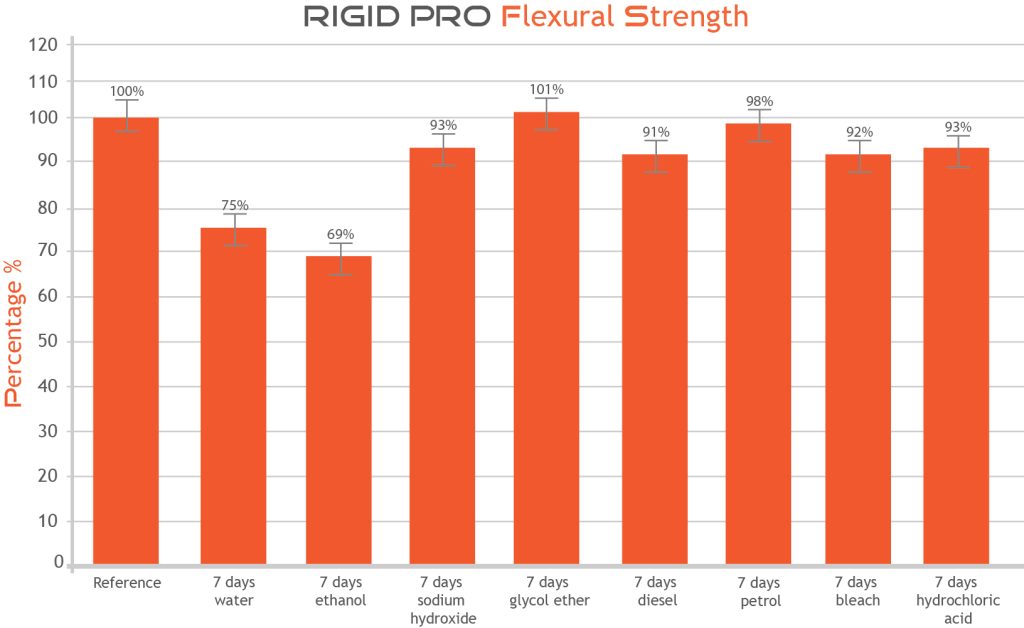

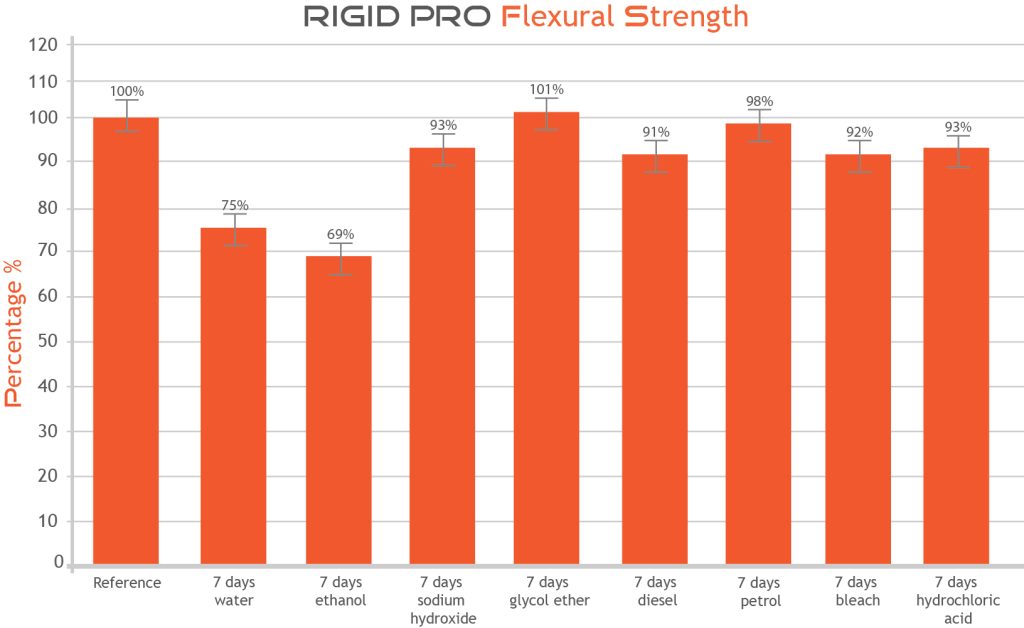

One of many key options of Liqcreate Inflexible Professional is its resistance to a wide range of chemical compounds, together with gentle acids and bases, in addition to petrol and diesel. This property positions it as a great materials for purposes within the oil and fuel trade, in addition to the chemical sector. The flexibility to design and produce customized chemical-resistant elements inside days affords an economical answer that was beforehand unavailable, says the corporate.

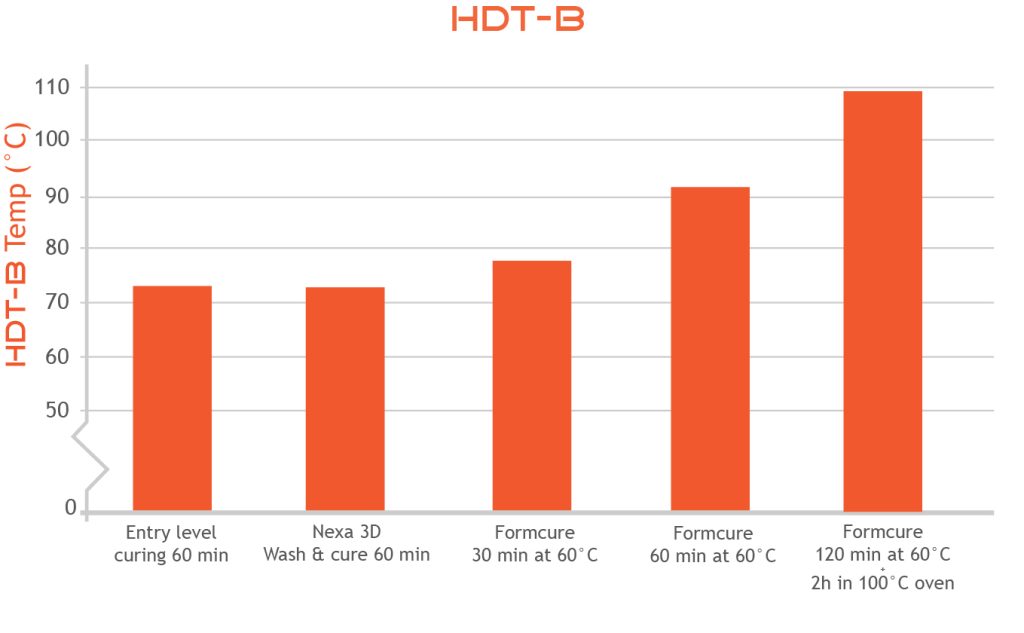

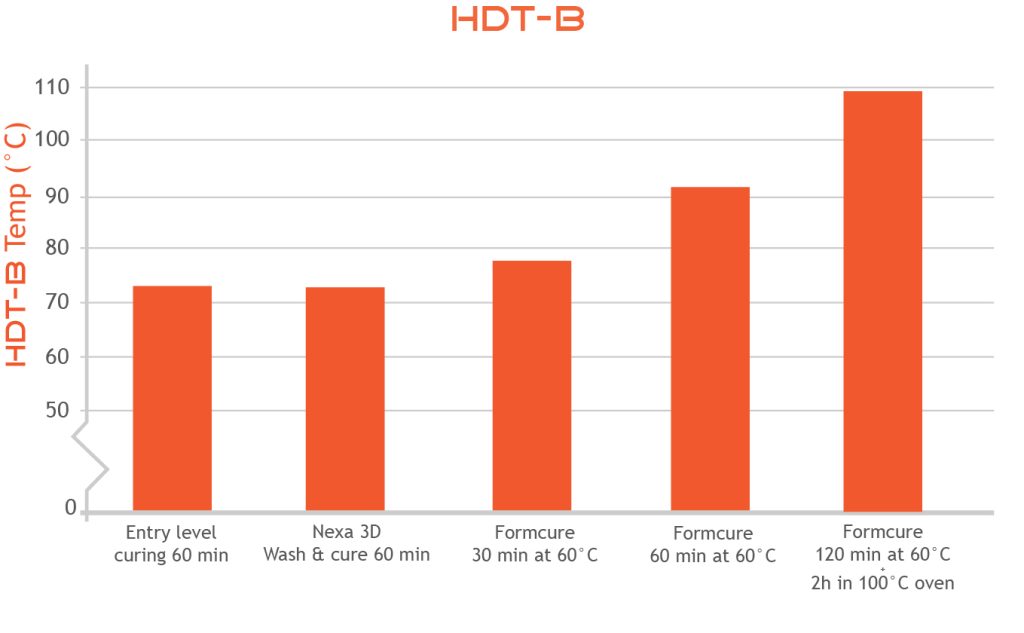

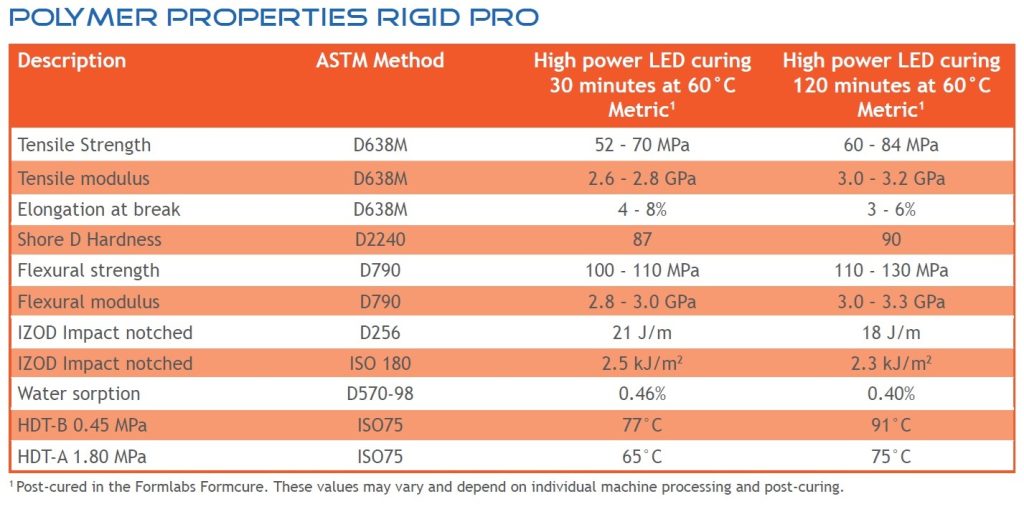

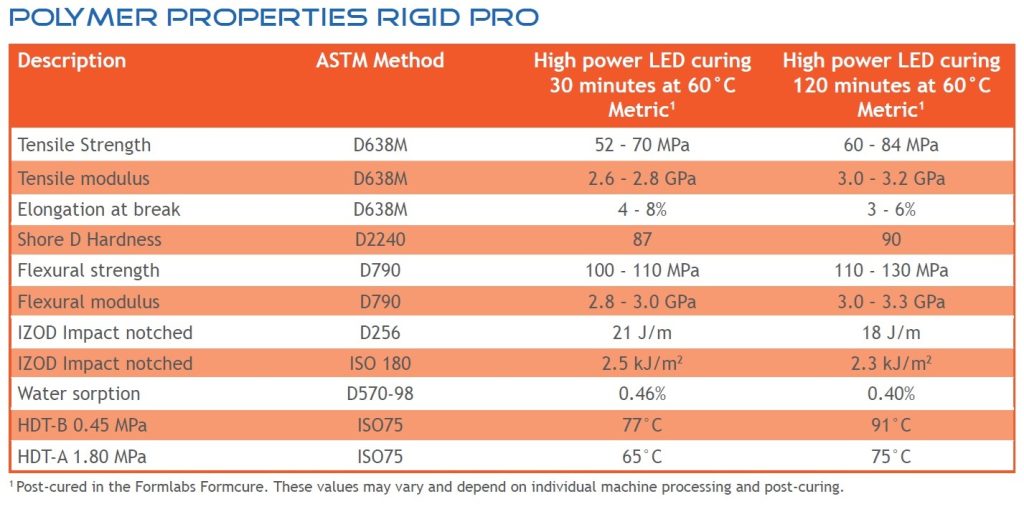

Furthermore, the warmth deflection temperature (HDT-B) of Liqcreate Inflexible Professional is 77°C after post-curing with UV gentle utilizing an entry-level curing unit. This worth could be considerably enhanced to 91°C utilizing a Formlabs Kind Remedy or equal unit, which UV cures and heats on the identical time. An non-compulsory thermal curing step can additional elevate the HDT-B to 109°C. These properties make the resin appropriate for purposes requiring good thermal resistance, reminiscent of automotive under-the-hood parts and medium-temperature casting and molding.

As a result of its mixed chemical resistance, high-temperature tolerance, and superior 110 MPa flexural energy, Liqcreate Inflexible Professional finds purposes in customized machining and manufacturing facility tools elements. Machining trade elements subjected to static hundreds could be designed, 3D printed, and post-processed in a single day, thereby eliminating the necessity for a considerable stock of spare elements.

For customers in search of resin compatibility inside a 385-420nm wavelength vary, Liqcreate Inflexible Professional presents a viable possibility. This contains Digital Gentle Processing (DLP), Liquid Crystal Show (LCD), and laser-based techniques, functioning inside a wavelength vary of 385-420nm. The resin’s versatility extends to working with entry-level machines from manufacturers like Anycubic, Elegoo, and Creality, in addition to skilled techniques from Asiga, Nexa3D, and UnionTech Martrix. Particulars on particular printing parameters could be discovered on the Liqcreate web site.

Liqcreate’s customization and collaboration drive

Customization choices can be found for Liqcreate Inflexible Professional, permitting OEM companions to rebrand and optimize the resin for numerous use instances and 3D printer compatibility. Liqcreate moreover affords customized growth providers. These providers cater to the creation of non-standard formulation tailor-made to particular purposes. Clients can request polymers with particular traits, influencing each printing velocity and the ultimate product’s properties.

By working independently and possessing in-house analysis and growth capabilities, Liqcreate fosters clean collaboration with 3D printer {hardware} producers. This eliminates potential competitors or conflicts, permitting Liqcreate to rapidly scale the manufacturing of customized resins and ship massive portions in a well timed method.

Register now for our Additive Manufacturing Benefit on-line occasion for insights on AM developments in aerospace, area, and protection sectors from trade leaders!

Be a part of the Knowledgeable Committee for the 2024 3D Printing Trade Awards to assist choose the winners!

What 3D printing tendencies do the trade leaders anticipate this 12 months?

What does the Way forward for 3D printing maintain for the following 10 years?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits Liqcreate’s new Inflexible Professional resin. Picture by way of Liqcreate.