UpNano GmbH in Vienna, Austria, has co-developed a novel manufacturing course of for 3D-printed fused quartz objects. This revolutionary expertise allows the manufacturing of high-precision formed components within the mm and cm vary.

The method relies on Glassomer GmbH’s (Freiburg, Germany) innovation and has been modified for two-photon polymerization (2PP) 3D-printing utilizing UpNano’s NanoOne high-resolution printing system. These are the very best efficiency 2PP 3D-printers in the marketplace, able to printing greater than 15 orders of magnitude.

Manufacturing minuscule and sophisticated 3D objects in glass is a difficult course of. It’s much more difficult if the required materials is to be high-quality fused silica (SiO2) glass, which has an exceptionally excessive melting level. The one potential strategies that can be utilized are based mostly on non-commercially obtainable tools and embody melting glass fibers utilizing laser beams or fused deposition modeling to supply soda lime glass.

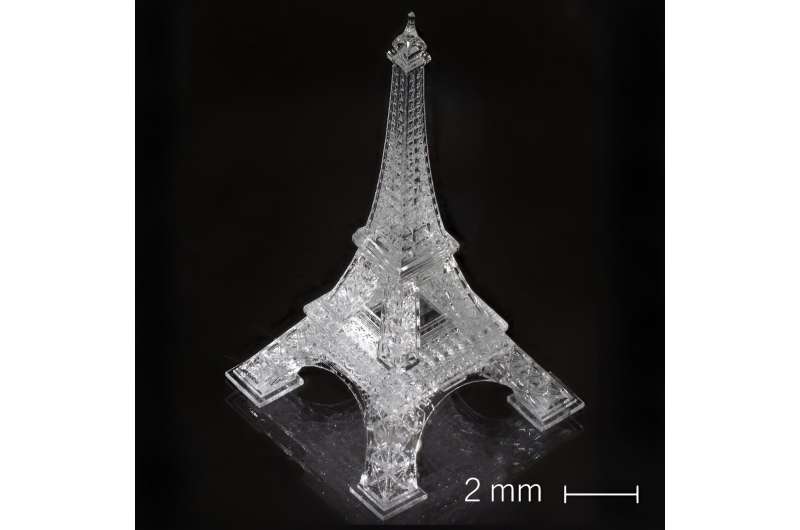

These strategies typically lead to last merchandise with tough surfaces which are undesirable. Now, UpNano and Glassomer have developed a speedy 3D printing course of to supply easy fused silica components within the mm and cm vary with options within the μm vary.

“It is a three-step course of,” explains Markus Lunzer, crew lead of Supplies & Software at UpNano. “Step one is to design and print the specified construction utilizing all the benefits 2PP 3D-printing gives. The second step is to take away natural binder materials adopted by a excessive temperature sintering course of, the third step.”

On the core of it is a newly developed nanocomposite “UpQuartz.” Along with SiO2 nanoparticles, it comprises a specifically designed polymer matrix that enables the composite to be 2PP 3D-printed within the first place. The printing course of produces a “inexperienced half” that already has the form of the ultimate and desired construction.

To acquire the fused silica product in the long run, the polymer matrix should be eliminated. Heating the inexperienced half to 600°C successfully removes the polymer matrix, abandoning the “brown half.” This consists of SiO2 nanoparticles within the form of the ultimate product. The construction is sintered and fused after publicity to 1,300°C.

Throughout post-processing, the item undergoes isotropic shrinkage of roughly 30%. This will simply be compensated for by an applicable upscaling of the inexperienced half utilizing UpNano’s software program.

“This revolutionary manufacturing course of we developed,” says Lunzer, “is ideally fitted to bigger 3D-printed glass components that require high-resolution and high-precision, within the fields of engineering, and chemical, medical or analysis functions.”

Fused silica gives superior optical properties, together with biocompatibility in addition to excessive chemical inertness and distinctive warmth resistance, making it an excellent materials for an unlimited vary of functions. This new growth marks a big development within the potential of 2PP 3D printing, following UpNano’s latest success in advancing the fabric testing of 2PP 3D-printed components utilizing UpNano printers and resins for macroscopic check specimens.

As well as, the corporate’s printers have just lately been used to attain a big milestone in 2PP 3D-printing by producing holistic embedded microfluidic chips in addition to tungsten and platinum microstructures with (sub-)μm decision.

The manufacturing of fused silica objects by 2PP 3D printing was a joint growth between UpNano and Glassomer. The German firm has beforehand enabled the manufacturing of fused silica objects by using applied sciences comparable to mushy lithography, injection molding, in addition to typical 3D-printing. Now, the joint materials growth from UpNano and Glassomer additionally permits using high-precision 2PP 3D-printing to supply fused silica objects.

This collection of developments exemplifies UpNano’s innovation capital within the extremely aggressive 2PP 3D-printer market, complemented by the continued and rising business success of the NanoOne printer vary. The truth is, gross sales in 2023 have been up 57% on the earlier 12 months and clients are actually served on 5 continents.

All NanoOne printers are geared up with patented adaptive decision expertise, which permits the laser beam to be expanded by an element of 10 for any given goal. A latest software program replace has enabled seamless stitching, and given all of the obtainable modules, the NanoOne vary of printers is now thought-about probably the most versatile and quickest 2PP 3D-printer in the marketplace.

“The velocity, decision, and flexibility of our printers make them highly effective instruments for the mass manufacturing of extremely exact components. Our ever-expanding vary of supplies extends the vary of functions. Sooner or later, we will even develop the vary of providers we provide,” provides Bernhard Küenburg, UpNano’s CEO.

Supplied by

UpNano GmbH

Quotation:

Novel course of for 3D-printing macro-sized fused silica components with hi-res options (2024, July 23)

retrieved 23 July 2024

from https://techxplore.com/information/2024-07-3d-macro-sized-fused-silica.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.